Stockpile end cone correction

Consistency

is an important and inevitable factor in any process plant. To meet a

consistent quality output of the product (for example steel or cement) the raw

material shall be fed continuously for processing in the required ratio.

Consider a case in which the raw materials are stored in the stockyard in number of

layers and during reclaiming if the consistency in blending is disturbed after

sometime of reclaiming. The result will be change in product quality.

Case

study:

Form

a stockpile of 40m (Width) x 12m (Height) x 250m (Length) with 6 layers and

discuss the consistency (mixture of all 6 layers of material) during reclaiming operation.

Machines

used for stacking & reclaiming,

Stacker -

Luffing Stacker or Twin Boom Stacker

Reclaimer - Bridge Scrapper Reclaimer or Barrel Reclaimer

or Wheel on Bridge Reclaimer

(Note:

above mentioned reclaimers are with harrow arrangement)

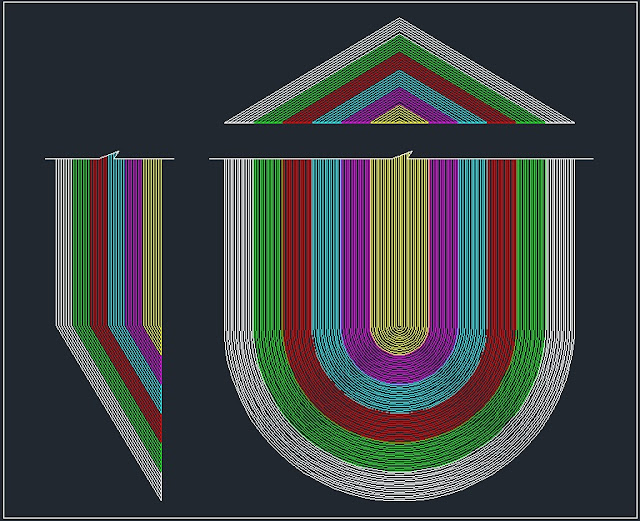

STOCKPILE:

Below sketch shows a stockpile of 40m x 12m x 250m (repose angle considered is

31°)

Side

A - Starting point of reclaiming operation.

Side

B - End point of reclaiming operation.

CASE

1:

Stockpile formed WITHOUT compensating the travel

length and the reclaiming operation.

Referring

the above sketches @side‘A’ and @side‘B’, it is clearly visible

that,

· @side‘A’, the consistency in reclaiming starts only after the reclaimer travelled

for a particular distance. For the given stockpile configuration, this distance

is 20m i.e., we get consistency in reclaiming only after travelling a distance of approx. 20m.

· @side‘B’, the consistency in reclaiming ends after the reclaimer travelled for a

particular distance. For the given stockpile configuration, this distance is approx.

20m from the stockpile end i.e., we get consistency in reclaiming only up to a particular travel distance.

· In

total the consistency in reclaiming is only for 210m out of total 250m length

of the stockpile.

CASE

2:

Stockpile

formed BY compensating the travel length and the reclaiming operation.

Referring

the above sketch @side‘B’, it is clearly visible that,

· @side‘B’, the consistency in reclaiming ends after the reclaimer travelled for a

particular distance. For the given stockpile configuration, this distance is approx.

40m from the stockpile end i.e., we get consistency in reclaiming only up to a particular travel distance.

· Consistency in reclaiming is only for 210m out of total 250m length of the

stockpile.

CASE

3:

Stockpile

formed BY COMBINATION of compensated and non-compensated travel length and the reclaiming

operation.

Referring

the above sketch @side‘B’, it is clearly visible that,

· @side‘B’, the consistency in reclaiming ends after the reclaimer travelled for a

particular distance. For the given stockpile configuration, this distance is approx.

20m from the stockpile end i.e., we get consistency (mixture of all 6

layers of material) only up to a particular travel distance.

· Consistency in reclaiming is for 230m out of total 250m length of the

stockpile.

Conclusion:

Comparing

all above cases, it shall be concluded that the consistency in reclaiming is

maximum when the stockpile is formed by a combined compensated and non-compensated

method of stacking.

***

REFERENCE PHOTOGRAPHS

***

Comments

Post a Comment